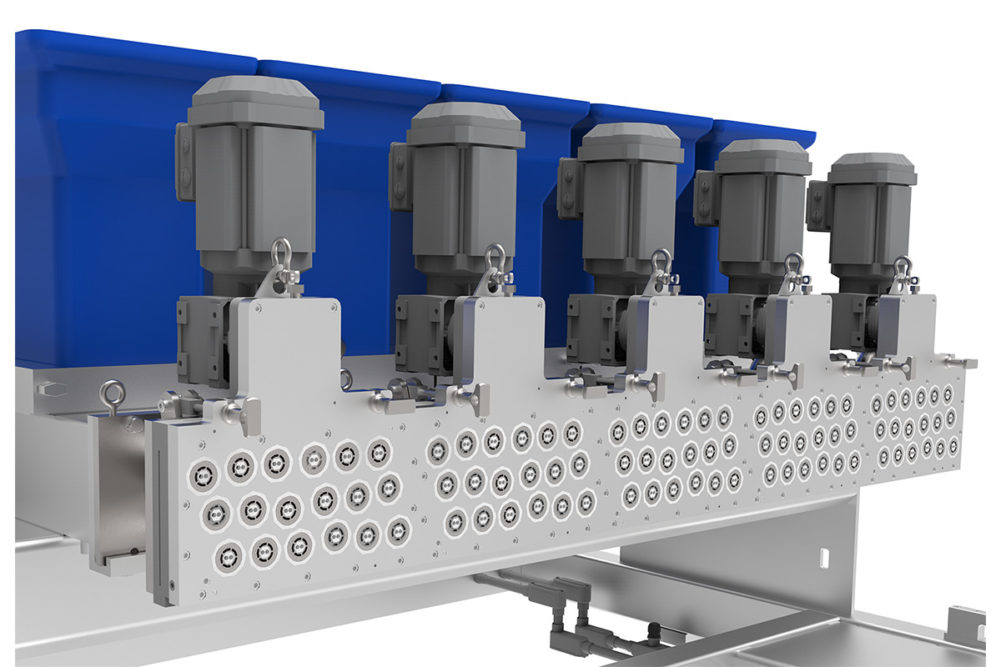

Reading Bakery Systems (RBS) is debuting an 18-nozzle rotating die that will increase throughput capacity up to 33% compared to the former 12-nozzle industry standard on the same sized production line, according to the company. The new nozzle die can mount directly on all standard RBS low pressure extruders.

“We are excited to offer this new product offering to our customers looking to increase capacity or create new products,” says Nico Roesler, North American pretzel and snack equipment sales manager. “The twisted products are very popular because of their unique texture and ability to hold tasty seasonings.”

The 18-nozzle design extrudes a continuous rope of dough to create “spirally wound shapes” that can be cut into twisted pretzel and stick products, according to the company. Capabilities such as the number of rotations and speed of extrusions can be independently controlled, allowing for the production of many different shapes and textures.

The rotating die incorporates stainless steel, gear-driven nozzles that contain internal inserts crafted out of Food and Drug Administration approved sanitary plastics. While in action, the pieces are lubricated using a food-grade semi solid lubricant, eliminating any chance of product contamination.